The Garmin G1000/Perspective combined with the Garmin GFC 700 Autopilot can be a great tool in descent planning. When you want to end up at pattern altitude a certain distance from the airport or you get a clearance to cross a fix at a certain altitude, Garmin VNV is a great tool. Here’s how to use it.

VFR Garmin VNV Use

Let’s say you want to end up at pattern altitude 3nm from your destination, but you don’t want to descend down into the bumps before you have to. Here’s how to set it up:

- Go to the Flight Plan page on the MFD

- Press the ATK OFST soft key on the bottom of the MFD. It stands for Along Track Offset, which, in laymen’s terms, means you are setting a point along your track a certain distance from your destination. In this case, it will be 3nm

- Input the distance using either the keypad or the small FMS knob and press enter

- Select the altitude you want to be at (in this case pattern altitude) and press enter

- You will see a point 3nm before you destination appear on your magenta line and a Top Of Descent (TOD) appear where you need to start your descent

- 1 minute before the Top Of Descent, an indicator will appear next to your altimeter

- To have the GFC 700 Autopilot fly the descent for you, you have to do two things

- Set the Altitude bug for the desired altitude

- Press VNV on the autopilot

- All you have to do now is manage power

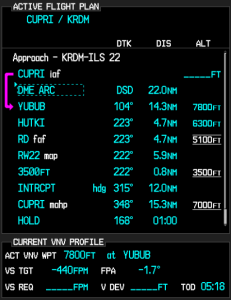

IFR Garmin VNV Use

Let’s say you are told to cross a fix at a specific altitude. Here’s how to use Garmin VNV to plan it out.

- Go to the Flight Plan page on the MFD

- Turn the cursor on and highlight the altitude blank next to the fix in the flight plan

- Input the desired altitude

- You will see a Top Of Descent (TOD) point appear along your course where you need to start your descent

- 1 minute before the Top Of Descent, an indicator will appear next to your altimeter

- To have the GFC 700 Autopilot fly the descent for you, you have to do two things

- Set the Altitude bug for the desired altitude

- Press VNV on the autopilot

- All you have to do now is manage power